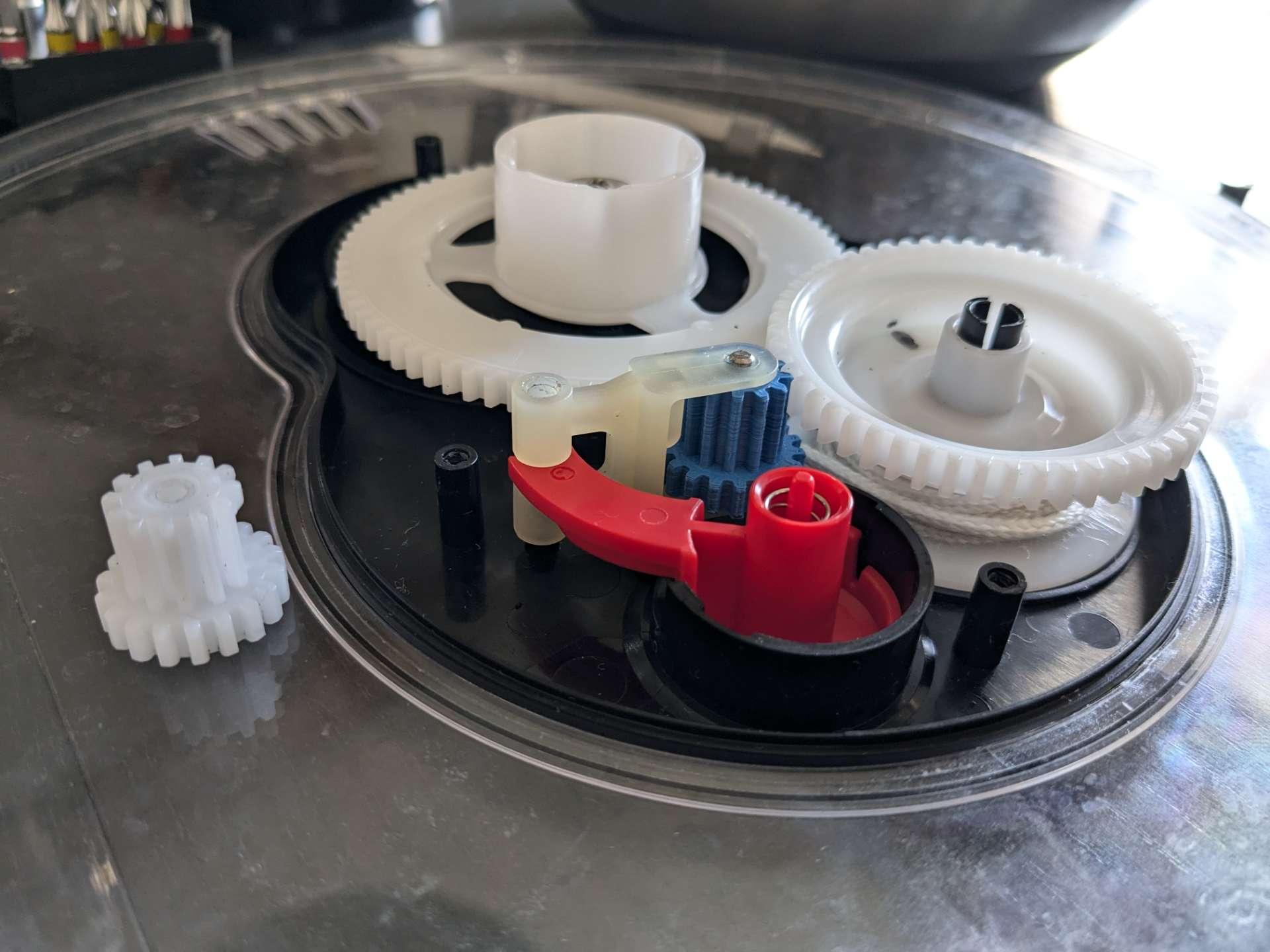

Our salad spinner has a broken gear, and someone has already designed a replacement part for 3D printing: https://www.thingiverse.com/thing:2234602

Ordering it from a 3D printing service would cost around €15, which feels excessive, so I'm planning to print it myself. I have no experience, but some colleagues do, and we have printers in my office that I can use, so I expect all the materials will be available.

I'll track the time I spend on this idea from market creation, resolving to the total time spent until the new part is tested. I'll include time spent learning about the process and disassembling/reassembling/testing, and exclude time spent doing unrelated things while waiting for prints. If I do not fix it before market close, or if I choose to order the part instead of printing myself, I'll resolve N/A. If the time falls on a bucket boundary, I'll select the higher bucket. I'll place an initial bet on the lowest bucket as incentive to not waste too much time, but I will trade no further.

🏅 Top traders

| # | Trader | Total profit |

|---|---|---|

| 1 | Ṁ51 | |

| 2 | Ṁ34 | |

| 3 | Ṁ21 |

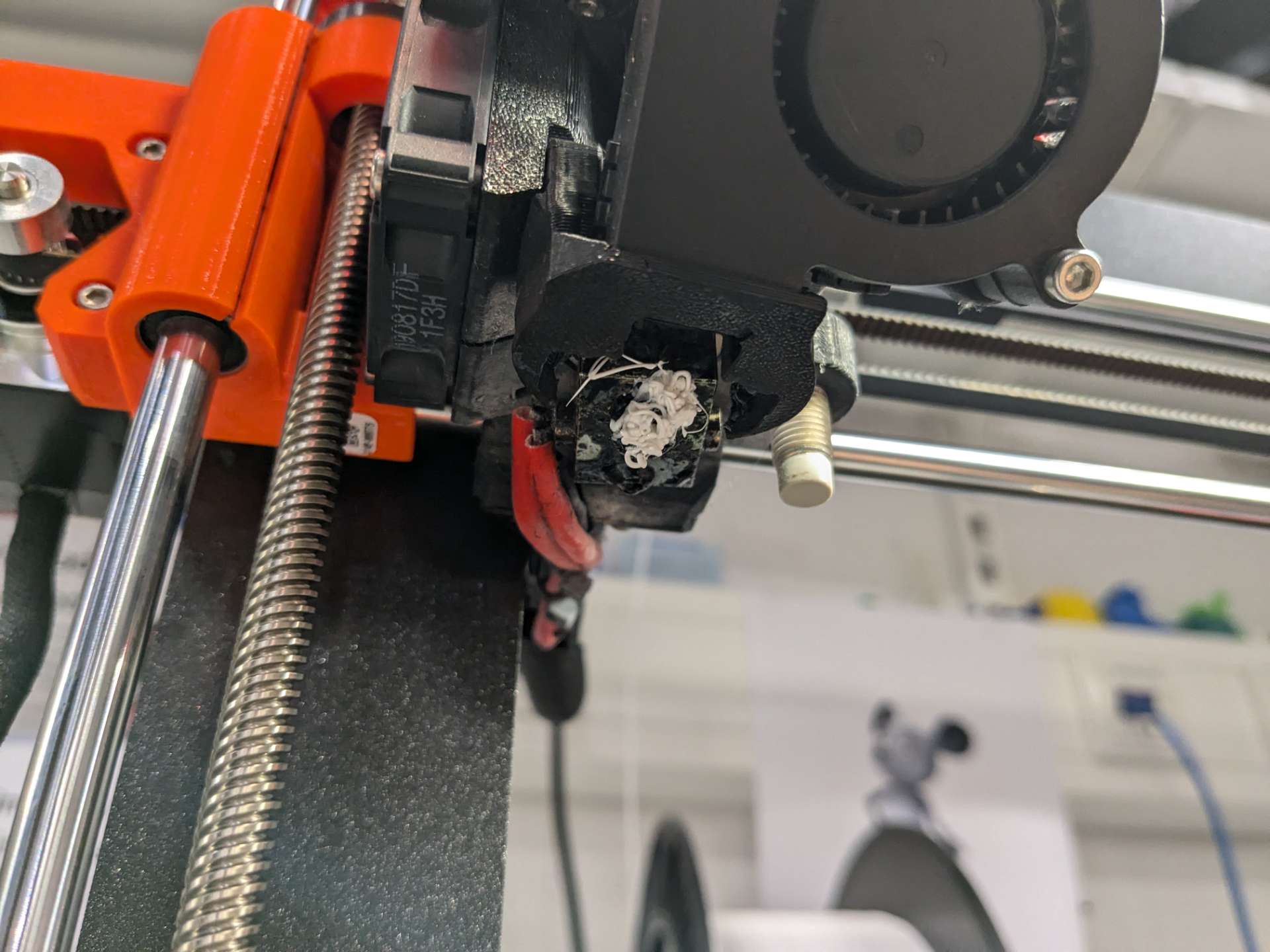

The part works great! The left shows the old path with some missing teeth on the right hand side. However, it was very tricky to install due to an interference fit for the axle. The designer's video didn't explain the installation but it showed them drilling through the middle of the part, and I ended up using a hammer to push the pin through, but had to remove the axle to fit it into the bracket. Installation and testing took 24m39s.

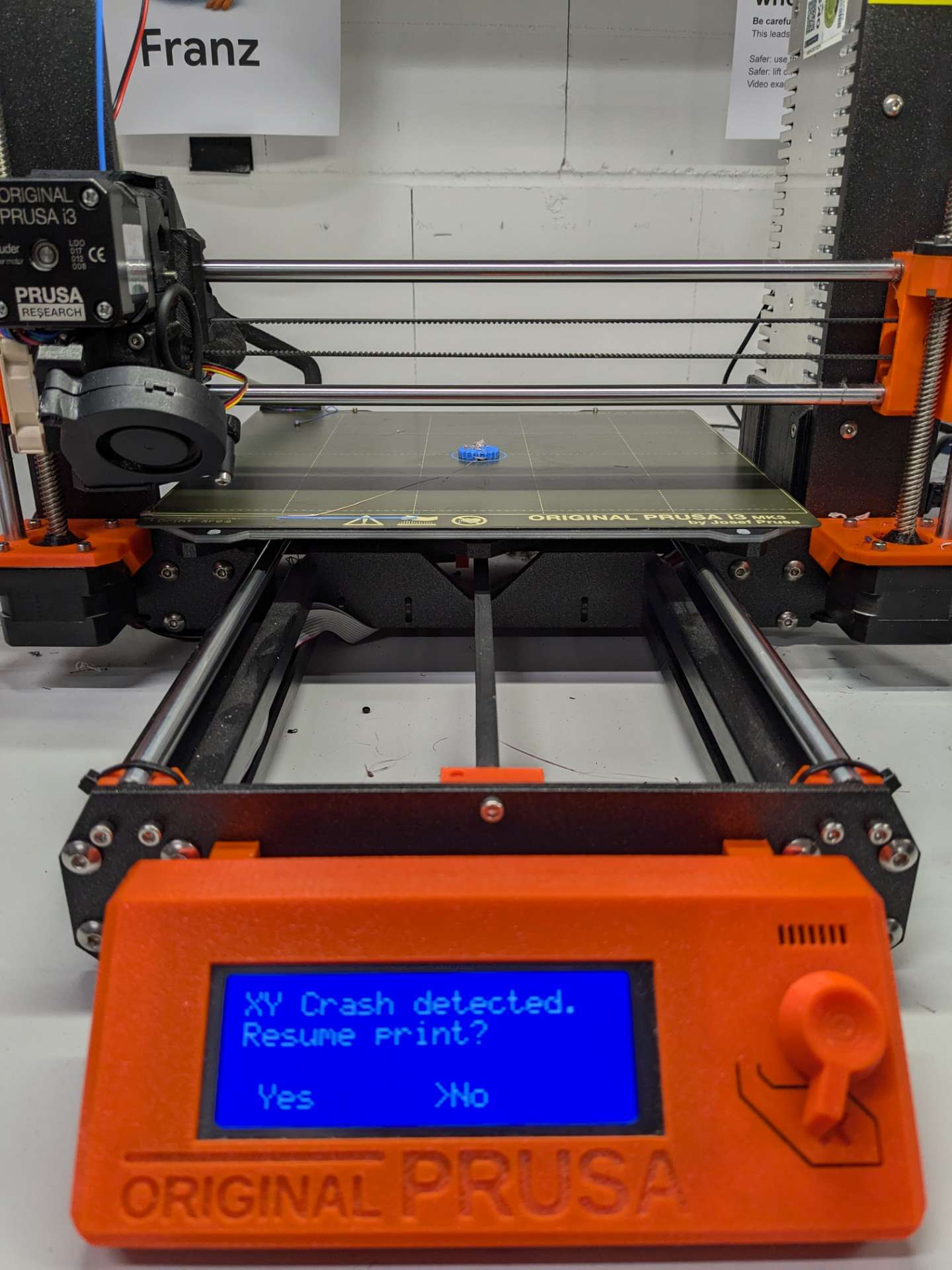

I spent 11m03s (up to 15m14s so far) reading the safety instructions and docs for the printer (a Prusa MK3, don't touch the hot bed, watch it in case it catches fire) and running the slicer, with some guesswork on what appropriate "shell thickness" is (I changed from the default 0.6mm to 1.2 mm in the hope it would be more durable). Next step is to try the first print tomorrow morning.

I spent 4m11s discussing the project with a colleague who owns a 3D printer, who advised me to pay attention to the filament used by the designer, as if this differs in type to the filament I used (apparently PLA is most forgiving) then I will need to figure our how to change the slicer settings. There are computers next to the printers that already have the slicer that I can use, so I'm a bit more optimistic about the 1hr target now than I was before.